CNC Routering

Here at Breckwerx, there are several benefits that you can expect to receive. Here are some of the advantages that we can provide for your business:

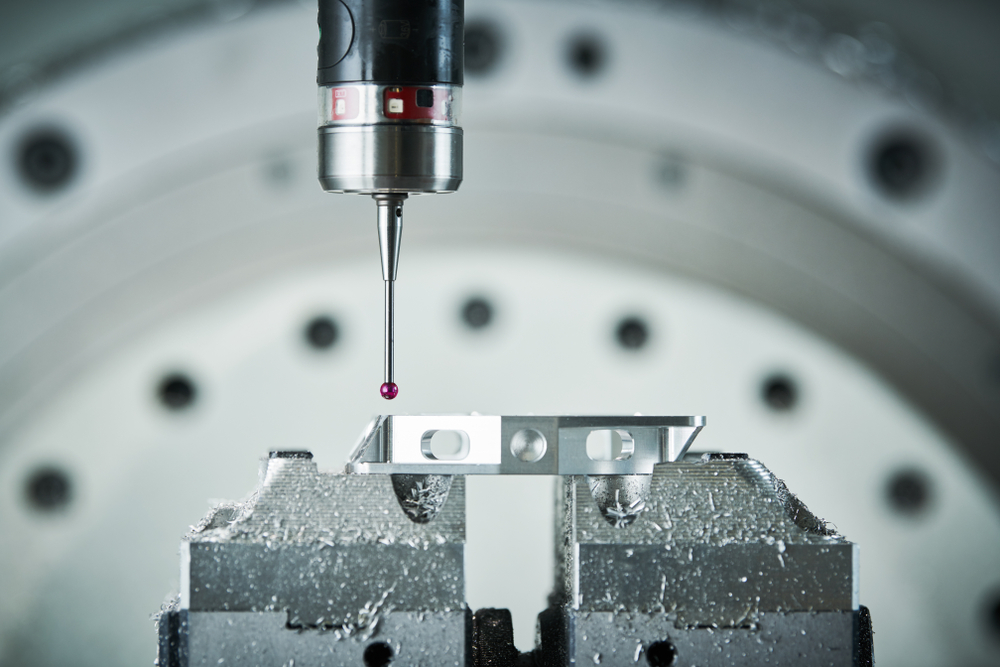

- Precision: CNC routering machines are highly accurate and precise, ensuring that your products will be produced to exact specifications. This level of precision can be especially important for products that require tight tolerances or complex geometries.

- Customization: CNC routering services can produce custom-designed products that are tailored to your specific needs and requirements, giving you the ability to create unique products that stand out from your competitors.

- Flexibility: CNC routering services can work with a wide variety of materials, including wood and plastics, providing flexibility in terms of the types of products that can be produced.